We are Manufacturer, Supplier, Exporter of Industrial Castings ( Foundry Castings ), SG Iron Castings ( Spheroidal Graphite Iron Castings ), Machined Grey & Ductile Iron Castings, Nodular Cast Iron from Kolhapur, Maharashtra, India.

SG iron casting, also known as spheroidal graphite cast iron, ductile iron, or nodular cast iron, is a type of cast iron with superior strength, ductility, and impact resistance:

SG iron is similar to gray cast iron, but it contains magnesium or cerium to create graphite nodules instead of flakes. SG iron has a higher yield strength than gray iron, is lighter than steel, and can be cast at a lower temperature. It also has excellent ductility, wear resistance, fatigue resistance, and toughness.

SG iron is used in a variety of industries, including automotive, construction, and agriculture. For example, it's commonly used in crankshafts. SG iron is produced directly from the melt, without heat treatment. Magnesium or cerium is added to the ladle just before casting.

SG Iron Grades : SGI-400/10, SGI-400/12, SGI-400/15, SGI-500/7, SGI-600/3, SGI- 700/2 & SGI- 700/3

Casting Weight Range : from 0.500Kg up to 85Kgs

- SG Iron Castings (Spheroidal Graphite Iron Castings) are known for their excellent strength, ductility, and impact resistance.

- Also referred to as Ductile Iron Castings, they contain nodular graphite which enhances mechanical properties.

- Applications:

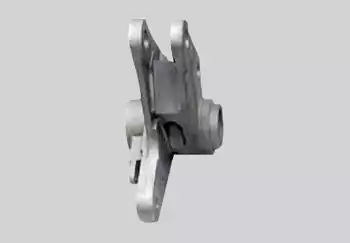

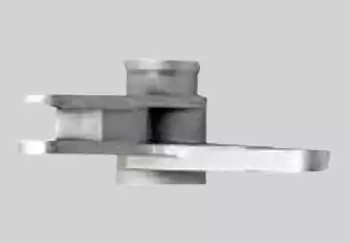

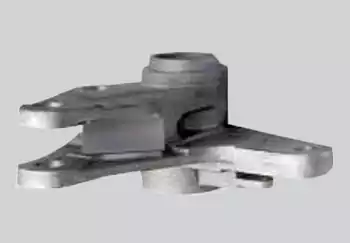

- Automotive Components: Crankshafts, axle housings, suspension parts, and brake components.

- Engineering Equipment: Gearbox housings, flywheels, and structural frames.

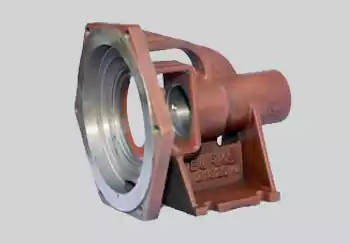

- Pumps & Valves: Pressure-resistant pump casings, valve bodies, and fittings.

- Agricultural Machinery: Tractor parts, rotavator flanges, and bearing housings.

- Construction Machinery: Load-bearing cast parts and brackets.

- Hydraulic Systems: Cylinder blocks and control valve casings.

- Features:

- High tensile and yield strength suitable for critical load-bearing applications.

- Excellent ductility and toughness make it ideal for shock and impact resistance.

- Good machinability enables accurate processing and shaping.

- Superior fatigue resistance compared to traditional grey iron castings.

- Corrosion resistance enhances durability in harsh environments.

- Cost-effective substitute for steel in many structural applications.

- Capable of withstanding pressure and thermal variations without cracking.