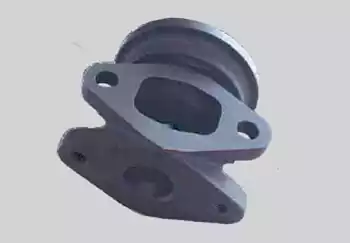

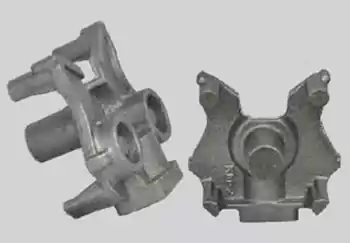

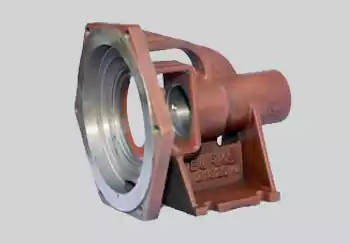

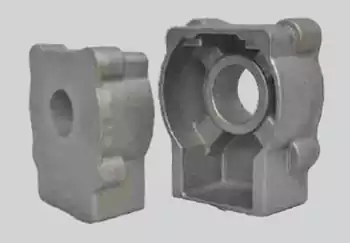

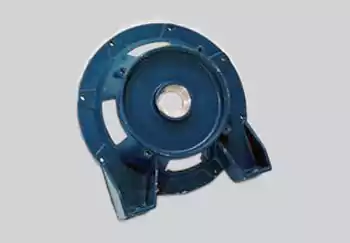

Cast iron is a class of iron-carbon alloys with a carbon content of more than 2% and silicon content around 1-3%. Its usefulness derives from its relatively low melting temperature. Cast iron casting majorly used in Automobile industries, automotive industries , Engineering Industries, Machines and Machinery manufacturing, Agriculuture industries, Pumps manufacturing Industries, Valve manufacturing, Hydraulic sectior etc.

Cast Iron Grades : FG-200, FG-220, FG-250, FG-260 & FG-300

Casting Weight Range : from 0.500Kg up to 85Kgs

- CI Castings (Cast Iron Casting) are known for their excellent strength, machinability, and wear resistance.

- Made from iron-carbon alloy with over 2% carbon and 1–3% silicon, ideal for high-volume production.

- Applications:

- Automobile Industry: Engine blocks, brake drums, and clutch housings.

- Engineering Machinery: Machine beds, gearboxes, and structural parts.

- Agricultural Equipment: Housings, frames, and rotating parts.

- Pumps & Valves: Pump bodies, impellers, valve bodies, and covers.

- Hydraulic Sector: Cylinder heads, base plates, and support components.

- Construction Equipment: Heavy-duty brackets and support castings.

- Features:

- Excellent castability due to low melting temperature.

- High compressive strength for load-bearing applications.

- Good machinability allows easy processing and finishing.

- Superior wear resistance in demanding working environments.

- Cost-effective material suitable for mass production.

- Vibration damping capacity ideal for machine bases and engine parts.

- Dimensional stability under thermal and mechanical stress.